vickers hardness test experiment procedure|vickers hardness testing machine diagram : importers Experiment No. 2 VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and . Wagering requirements: 50x (bonus + deposit) (restrictions apply) This bonus can only be used on these types of casino games: Slots, Keno, Scratch cards. You will have to wager 50-times the sum of your bonus and deposit to clear the bonus and be able to withdraw your winnings.; For example, if you deposit $100 and get a $400 bonus, you will have to .

{plog:ftitle_list}

WEB2 dias atrás · Hannah Palmer is represented by Elite Models. Build. Voluptuous. Height. 5 ft 8 in or 173 cm. Weight. 58 kg or 128 lbs. Race / Ethnicity. White. Hair Color. Blonde. Eye Color. Blue. Sexual Orientation. Straight. Distinctive Features. Curvy physique. Pouty lips. Brand Endorsements.

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .Experiment No. 2 VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and .In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond .

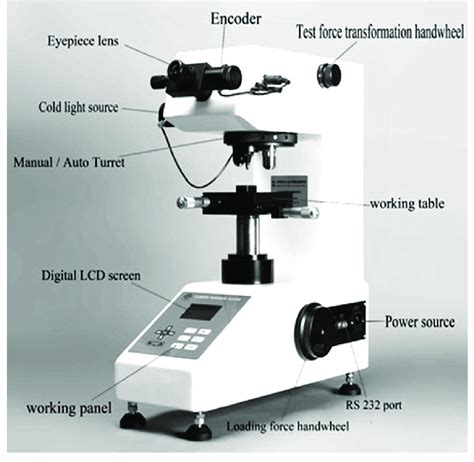

vickers hardness testing machine diagram

vickers hardness test procedure pdf

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro .

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .

The 3842 Vickers Hardness Tester is engineered to produce a clear indentation and a more precise measurement. By means of a load cell, closed circuit system for control, the CPU .

Vickers Hardness Test. The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers procedure can be used to test the hardness of metals and other equally hard materials. However, it was primarily designed to focus on softer materials like plastic specifically on their ability to resist .Figure 3.1: Schematic principles of operation of Vickers hardness machine. MATERIAL & METHODOLOGY Material and Apparatus Hardness testers: Vickers microhardness. Test Specimens: Metal specimen from Experiment .

A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it finds use in other materials like ceramics & some polymers, this test is widely employed in the metallurgical area.

Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as .The Vickers hardness test is a widely used standard test method for measuring the hardness of metals. It measures the ability of a material to withstand penetration by an indenter when it is pressed with a fixed load. You can also use it to measure the indentation hardness of non-metallic materials, provided they are sufficiently dense.When selecting a hardness test method, important considerations include: The type of material to be hardness tested; . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must not differ by more than 10.0% from each other.Experiment Six (6) Hardness Testing Introduction . Each hardness test method, or scale, is defined with a particular type of indenter, a specified minor load, and a specified major load. The measured indentation size is then converted to a hardness . Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o.

Hardness of the samples has been evaluated by using Vickers Hardness Test. The Corrosion behaviour of as-received and thermally oxidised samples have been evaluated by using weight loss method.1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized: Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de.

vickers hardness test explained

Vickers hardness test is a standard method for measuring materials' hardness, which is commonly used to measure the hardness or softness of substances like metals, minerals, and plastics. Here's the article for you to everything about Vickers hardness testing, including basics and principle, Vickers hardness test procedure, formula and calculation.

United States 1 E92−17 C1326 Test Method for Knoop Indentation Hardness of 3.1.4 Vickers hardness number, HV,n—the calculated result Advanced Ceramics from a Vickers hardness test, which is proportional to the test C1327 Test Method for Vickers Indentation Hardness of force applied to the Vickers indenter divided by the surface Advanced .The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is usually easier to use compared to other hardness tests. The reason is the required calculations are not dependent on the size of the indenter.

It may be necessary to divide the complete range of the micrometer microscope into several subranges, each having its own factor. 15.2 Verification by Standardized Test Block Method: 15.2.1 A Vickers hardness testing machine used only for routine testing may be checked by making a series of impressions on standardized hardness test blocks (Part .

In conclusion, the Vickers hardness testing method is a powerful technique for assessing the hardness of various materials. Its principles are grounded in precise indentation measurements, allowing for accurate material characterization and evaluation. With its wide range of applications in material science, manufacturing, and research, the . Mechanical hardness testing is fundamental in the evaluation of the mechanical properties of metallic materials due to the fact that the hardness values allow one to determine the wear resistance .This article explains the procedure to perform the Rockwell hardness test on metals. Rockwell Hardness Test Procedure. The Rockwell hardness test employs the principle of differential-depth method. During the test, the .Hardness Test 2/5 the microscope is in millimeters. The larger diameter indentation corresponds to a softer material and lower Brinell number. VICKERS HARDNESS TEST The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope. For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .3.1.3 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.

The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. . IS 1501:2002, method for Vickers hardness test for metallic materials. Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General .Vickers hardness testing, also called microhardness testing, is typically used for small parts, thin sections, or or case depth work. The Vickers method is based on an optical measurement system. The Microhardness testing procedure, ASTM E-384, specifies a series of light loads in which a diamond indenter makes an impression that is measured .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low-load and conventional (macro) hardness range. Applications of Vickers methods depending on the respective load range.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure t.The laboratory hardness tester supported by relative software equipped with a microscope giving magnification between 10 to 40x, applied the Vickers Test method on ferro us materials. The hardness difference between the core and the outer surface of a material gives the case depth .

webPatrocinense wint de wedstrijd. +25. +70. Ervaar de spanning van live wedden bij Napoleon Games. Wed in real-time op jouw favoriete sporten. 🏆💰.

vickers hardness test experiment procedure|vickers hardness testing machine diagram